It is worth noting that the polishing of mold surface is not only affected by the polishing equipment and technology, but also affected by the mirror degree of mold material, which has not attracted enough attention, that is to say, the polishing itself is restricted by the mold material. Although new treatment technologies are emerging to improve the surface performance of precision die parts, nitriding, carburizing and hardening film deposition are the main applications in the manufacture of high-precision die parts. Because of nitriding technology can form the surface of the excellent properties, and nitriding process with high precision mold fittings steel quenching process has the good coordination, nitriding temperature is low, at the same time without fierce cooling after nitriding, the high precision mold parts deformation, thus high precision mold parts surface strengthening is earlier by nitriding technology, is also the most widely used.

In addition to the requirement of high strength and toughness, the surface performance of high precision mold parts is very important for their working performance and service life. The improvement of these properties is very limited and uneconomical only depending on the improvement and improvement of matrix materials, while the surface treatment technology can often get twice the result with half the effort, which is also the reason for the rapid development of surface treatment technology. Die polishing technology is an important part of die surface engineering and an important post-treatment technology in die manufacturing process. Due to domestic polishing technology and materials, there are still some problems, so such as point-and-shoot camera lens injection mold, CD, VCD disc and tool transparency requirements of high injection mold is still a large part of the dependence on imports.

Mirror mould material is not only chemical composition problem, more major is require the use of vacuum degassing, argon gas protection when smelting ingot casting, vertical continuous casting and rolling, forging and a series of advanced technology, make the mirror steel with less internal defects, fine granularity, high degree of dispersion, metal impurities of fine grain size and uniformity is good wait for a series of advantages, polished to a mirror in order to achieve the requirement of steel. The surface treatment technology of mold parts is a systematic engineering to change the surface morphology, chemical composition, structure and stress state of high-precision mold parts through surface coating, surface modification or composite treatment technology, so as to obtain the required surface performance. Nitriding technology has gas nitriding, ion nitriding, liquid nitriding and other ways, in each way of nitriding, there are a number of kinds of nitriding technology, can adapt to the requirements of different kinds of steel different workpiece. From the way of surface treatment, it can be divided into chemical method, physical method, physical chemical method and mechanical method.

Mold accessories: Gas cap mould, die springs, stainless steel exhaust bolt, brass vent plug, cooling, thermal conductive paste, diamond paste, diamond grinding paste, mold counter, guide, guide mouth, eye mode, beryllium copper, copper screw electrode, grinding machine, filter paper, mould T blunt needle, SKH51 thimble, SKD11 punch, SUS420 gas cap mould, air pin, pneumatic plunger, stainless steel precision gas nozzle, tip, air valve, pneumatic pin, HUS plastic mold counter, tungsten wire attack, attack of hard gold, domestic gas cap, beryllium copper, tungsten steel roll grinders, HASCO German type gas cap mould, Z491 phosphorus beryllium copper valve, Alloy copper air tip, air nozzle, VA mold air cap, tungsten steel milling cutter, travel switch, limit switch, limit switch, stainless steel glass ball;

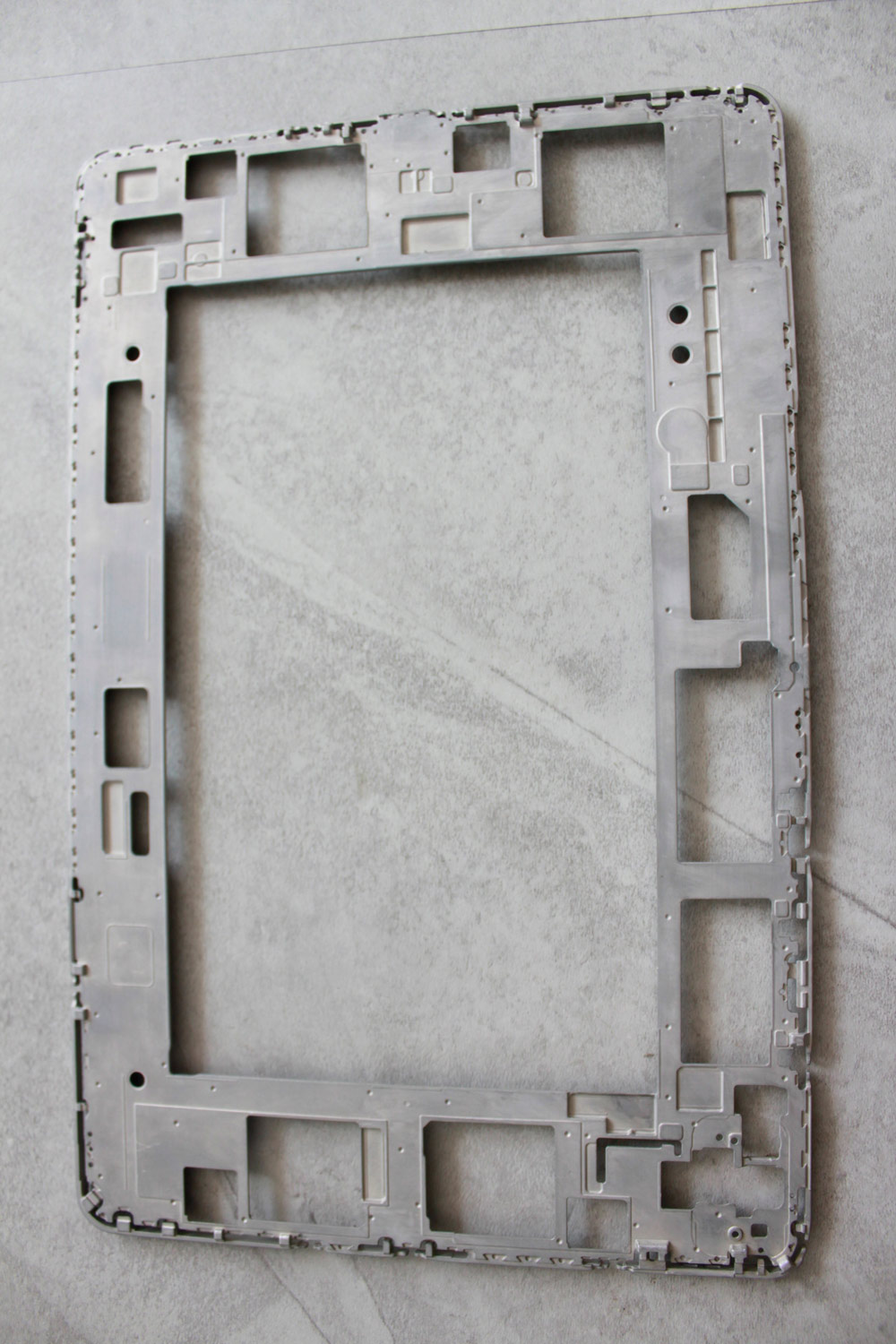

Dongguan Pengle precision components Co., Ltd. is a mobile phone precision mold manufacturing, processing, manufacturers. Over the past 15 years, Pengle has continuously introduced advanced technology and equipment from Germany and Japan, established a unique standardized quality control center, recruited and trained talents who have been focusing on mobile phone board and mobile phone precision accessories for more than 10 years, optimized THE ISO management mode, and built a modular, transparent and modern factory with unique style in the industry.

In addition to the requirement of high strength and toughness, the surface performance of high precision mold parts is very important for their working performance and service life. The improvement of these properties is very limited and uneconomical only depending on the improvement and improvement of matrix materials, while the surface treatment technology can often get twice the result with half the effort, which is also the reason for the rapid development of surface treatment technology. Die polishing technology is an important part of die surface engineering and an important post-treatment technology in die manufacturing process. Due to domestic polishing technology and materials, there are still some problems, so such as point-and-shoot camera lens injection mold, CD, VCD disc and tool transparency requirements of high injection mold is still a large part of the dependence on imports.

Mold accessories: Gas cap mould, die springs, stainless steel exhaust bolt, brass vent plug, cooling, thermal conductive paste, diamond paste, diamond grinding paste, mold counter, guide, guide mouth, eye mode, beryllium copper, copper screw electrode, grinding machine, filter paper, mould T blunt needle, SKH51 thimble, SKD11 punch, SUS420 gas cap mould, air pin, pneumatic plunger, stainless steel precision gas nozzle, tip, air valve, pneumatic pin, HUS plastic mold counter, tungsten wire attack, attack of hard gold, domestic gas cap, beryllium copper, tungsten steel roll grinders, HASCO German type gas cap mould, Z491 phosphorus beryllium copper valve, Alloy copper air tip, air nozzle, VA mold air cap, tungsten steel milling cutter, travel switch, limit switch, limit switch, stainless steel glass ball;

Dongguan Pengle precision components Co., Ltd. is a mobile phone precision mold manufacturing, processing, manufacturers. Over the past 15 years, Pengle has continuously introduced advanced technology and equipment from Germany and Japan, established a unique standardized quality control center, recruited and trained talents who have been focusing on mobile phone board and mobile phone precision accessories for more than 10 years, optimized THE ISO management mode, and built a modular, transparent and modern factory with unique style in the industry.